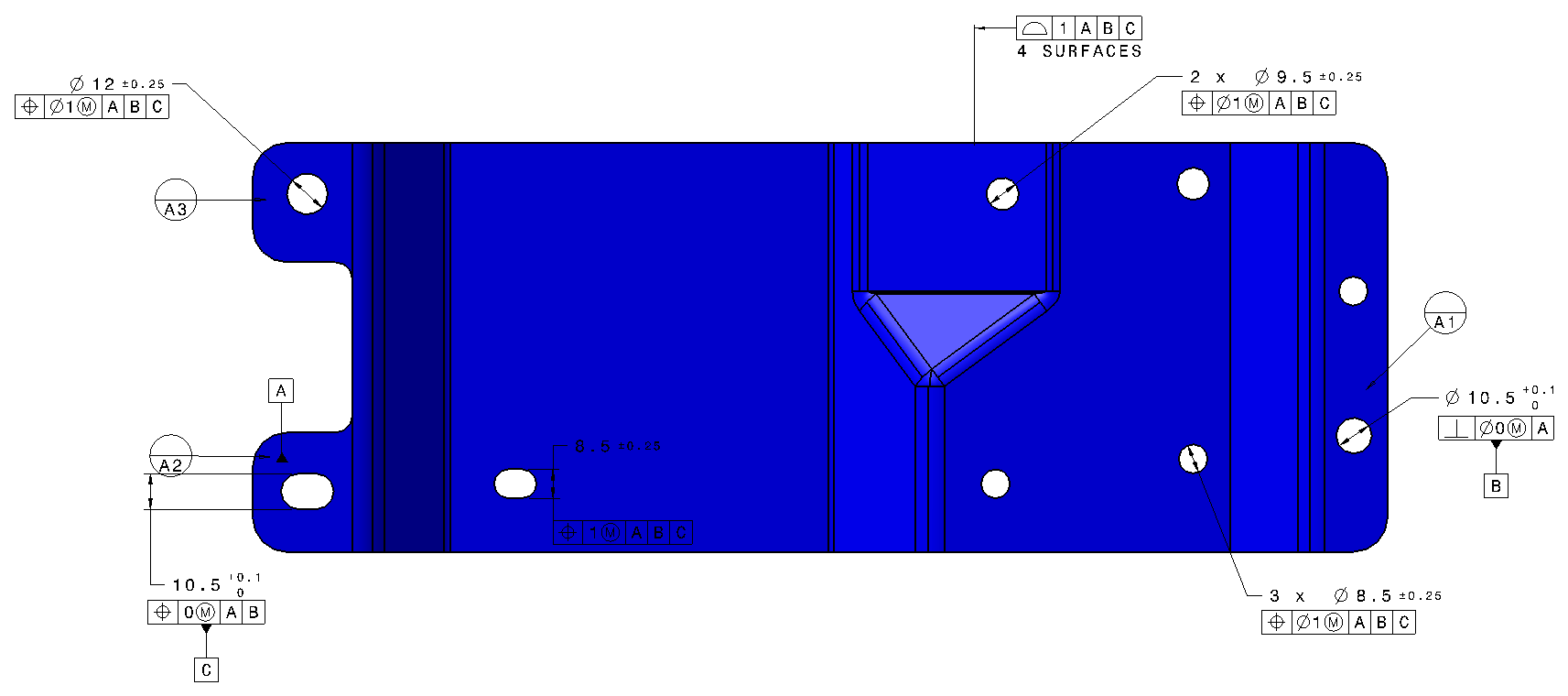

GD&T, Tolerance Stack-up Analysis

iSquare promises to provide best services at highly competitive costs. Our services range from Consulting, Training Dimensional Control Procedure Implementation, Process review and suggestions. DCS, USA is committed to support iSquare or work jointly for large and demanding services in Dimensional Management.

Creating baseline tolerance models and performing statistical and root cause analysis to bring the part issues upfront before investing into expensive tooling, fixtures and gages

Establishing major system and sub-assembly requirements for quality objectives.

Three-dimensional tolerance analysis for developing robust designs.

Identifying specific contributors and enhancing product quality while lowering costs.

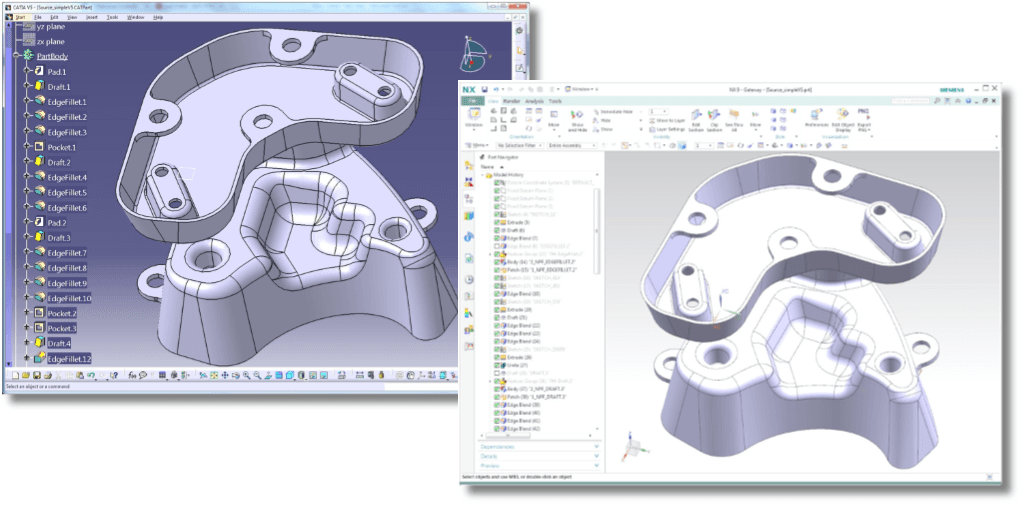

3D CAD Data Translation / Repairing

iSquare provides high quality CAD Geometry healing and translation services focused around robust products from TranscenData, USA. Our suite of translation and repair tools allows designers, analysts and engineers to exchange their CAD/CAM/CAE data quickly and easily, eliminating up to 90 percent of data rework.

- Multiple CAD imports

- Batch processing

- Intelligent model repair and healing

- Automatic processing Wizards

- User-controlled model Defeaturing

- Interactive fixing tools

- Multiple CAD/CAE exports

Process Automation

Our 3D translation and healing solutions guide users effortlessly through the import, repair, and export process, requiring minimal manual intervention.

With our vast array of automatic and interactive processing tools, we enable users to address almost every issue affecting CAD geometry, effective translation, and downstream reuse.

Key Features:

- Stitching models

- Creating missing geometry

- Building solids

- Setting tolerance deviations/requirements across different systems

- Identifying and correcting serious surface definition problems

- Reducing the complexity of geometry for downstream applications

Deliver Quality Translations throughout the Entire Process

- It is not just about translating and fixing. Clients can tailor our solutions to check product data quality (PDQ) using a comprehensive library of PDQ tests.

- Users can also specify the PDQ tests for assessment and set the controlling parameters and tolerances as needed. The completed test then guides the user through a list of potential resolutions to address the quality issues.

- This type of quality analysis automatically identifies entities in the model that fail to meet the requirements of the selected PDQ criteria and presents the results to the user both graphically and in a text report.

- Our quality analysis components also offer customization for in-house policies and/or international PDQ standards such as SASIG, VDA, and JAMA.

Product Data Quality Solution Overview

- Combines expertise in interoperability and process improvement with innovative technology to identify and resolve design and software issues.

- Tailored engagements ensure measurable ROI, addressing custom requirements to deliver solutions on time and within budget.

- Strategic, long-term solutions simplify complex scenarios and accelerate implementation for effective results.

- CADIQ technology identifies geometric issues impacting design reusability and addresses integrity, accuracy, and complexity criteria.

- Unique capabilities include comparing multiple models across formats, with synchronized graphical feedback to highlight issues.

- Easy-to-use interface mimics supported CAD systems, integrates into automated environments, and supports process quality improvement with metrics.